| Machinery Price List is as below table: | ||||||

| No. | Equipment name | Quantity | Total Rated Power | Total Price (FOB Qingdao) |

||

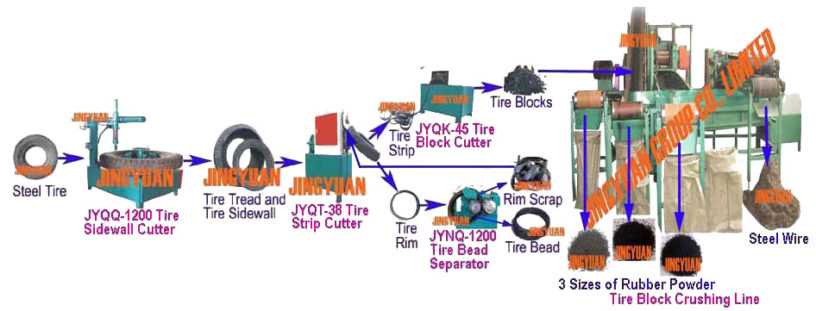

| (1). | JYQQ-1200 Tire Sidewall Cutter | 3 | Set | 16.5 | Kw | Please Contact us to inquire |

| (2). | JYQT-38 Tire Strip Cutter | 3 | Set | 16.5 | Kw | Please Contact us to inquire |

| (3). | JYQK-45 Tire Block Cutter | 3 | Set | 33 | Kw | Please Contact us to inquire |

| (4). | JYNQ-1200 Tire Bead Separator | 3 | Set | 45 | Kw | Please Contact us to inquire |

| (5). | JYXKP-560 Tire Block Crushing Line(Each Set Include One Jyxkp-560 Rubber Crusher,One Big Vibration Screen,One Returning Belt Conveyor, One Big Steel Wire Separator, One Small Vibration Screen And Three 2-Step Small Steel Wire Separator) | 3 | Set | 324.6 | Kw | Please Contact us to inquire |

| Total: | 15 | Set | 435.6 | Kw | Please Contact us to inquire | |

| Working Area:600m2 Worker:9-12person Average Power Consumption:300-330KW/hour. | ||||||

Remarks:

1). The capacity 3000-3600kgs/hour is based on 5-20mesh(0.85-4mm) output, if adjusted to 20-40mesh(0.35-0.85mm) output, the capacity will be 1500-1800Kgs/hour.

2). The total rated power is 435.6 Kw, but the Average Power Consumption is 300-330kw/hour only, because some machines don’t always work.

3). It is simplest tire recycling line, did not include fiber separator, only workable to recycle Radial Steel Tires, you can buy this tire recycling to start, if you want to recycle fiber tires or half-steel and half-fiber tires in future, you can add JYXF-500 Fiber Separator. Regarding the 3000-3600kgs/hour tire recycling plant with JYXF-500 Fiber Separator, please visit https://www.usedtirerecycling.com/3000-3600kgs-per-hour-simplest-tyre-recycling-plant-with-jyxf-500-fiber-separator/.

4). Above line can make 5-40mesh(0.85-4mm) rubber powder and also can screen out some 40-120mesh(0.12-0.85mm) superfine rubber powder, if you want to want to get much more 40-120mesh(0.12-0.85mm) superfine rubber powder in future, you can add JYZM Superfine Rubber Powder Grinding Line.

5). If you want to weigh and pack recycled rubber crumb into bags automatically, you can add one JYDL-25-50 Automatic Weighing and Packing Machine.

6). We only published some simplest tyre recycling plants on our website,if you have special requirement or require other type of tyre recycling plant, please let us know your requirement, so that we can send you right plant to your Email, Ok?

Do you want to want to see how this tyre recycling plant work? If so, please click following video to watch online.

Darius Georgiu

Where can yoy sell the products, rubber powder and steel dust, do you have also a business plan?

I am interested in buying a plant for 600-800 kg/hour

admin

Dear Darius Georgiu,

Glad to know you are interested in buying a tyre recycling plant for 600-800kgs/hour.

For the recycled rubber crumb, the best solution is using rubber tile making plant to make them into colorful rubber floor tiles, then sell them in local market or neighbor countries. Regarding the details of different capacity rubber tile making plant, please visit http://www.usedtirerecycling.com/rubber-tiles-manufacturing-process/ to browse on our website.

Regarding the recycled steel, the best way is sell them directly when you have them, you can contact local steel recycling company or steel casting company to sell them, or publish them on internet, so that the buyers can find your selling leads and contact you to buy.

By the way, I just send this post to you by Email, and from now on, hope you can contact us by replying my Email instead of leaving messages here on our website, Ok?

Hope you can understand and write soon.

Best regards,

Eric Chen

Harsh QuoraHarshEntrepreneur M5149720 Patel WhiteSafeUser

Is someone building new products /materials with these? Quora com profile Harsh-Entrepreneur

admin

Hello, Harsh, yes, some building new products/material with the recycled rubber crumb, the details is as below:

The recycled products from waste tires include Recycled Rubber Powder/Granule, Recycled Tire Beads, Recycled Tire Steel Wire, and Recycled Tire Fiber, all of these are expensive and shortage resources, demand exceeding supply in market, can be sold very easily.

The application of recycled Rubber Powder/Granule is as below:

1). Recycled Rubber Powder/Granule can be made into color flexible rubber floor tiles or paved rubber playgound directly. The rubber floor tile and rubber playground can overcome of the shortcomings of the hard texture of brick, and enables the user to walk or activity always in a safe and comfortable physical and psychological state, comfortable, and relaxed. Laying in the elderly and children’s sports facilities, play a good protective effect on the safety of the elderly and children. Not only can better play the skills of the competitors, but also can reduce the jumping and sports equipment may cause injury to the athletes. The most important features: non-slip, shock absorption, abrasion resistance, antistatic, silencers, noise barrier, Moisture barrier, separated from cold, heat insulation, non-glare, water, fire, non-toxic, non-radiation, strong weather resistance, anti-aging, long life, easy to clean, easy construction.

2). Recycled Rubber Powder/Granule can be mixed with asphalt, resins and other raw materials, make out waterproof coiled material, waterproof coating, waterproof seal materials, etc. These waterproof material include recycled Rubber Powder/Granule have excellent anti-aging properties, good mechanical resistance, etc.

3). Recycled Rubber Powder/Granule can be added into Asphalt to make Modified Asphalt, then pave high-grade highways and plane runway. The recycled Rubber Powder/Granule contains antioxidants, which can significantly slow down the aging of the road, make the road more flexible, anti crack, anti water peeling, reduce noise, increase the road surface abrasion resistance, etc. The wear life will be about 2-3 times of ordinary roads, can reduce the maintenance costs of the road 30-50%. And the vehicle braking distance is reduced by 25%, largely improve traffic security.

4). The recycled Rubber Powder/Granule can be made into reclaimed rubber, then make almost all rubber products, such as rubber sheet, rubber mat, machine pad, cushion pads, shoes base, cable skin, fenders, sound-absorbing materials of the mechanical properties, etc. And also can be add into natural rubber to make new tires.

5). Recycled Rubber Powder/Granule can be added into some plastics as additives, to improve the plastic technology features.

6).Recycled Rubber Powder/Granule can be added into Concrete to improve the technology features of concrete, to be used on Railway base, etc.

Many, Many more other applications……..