Application

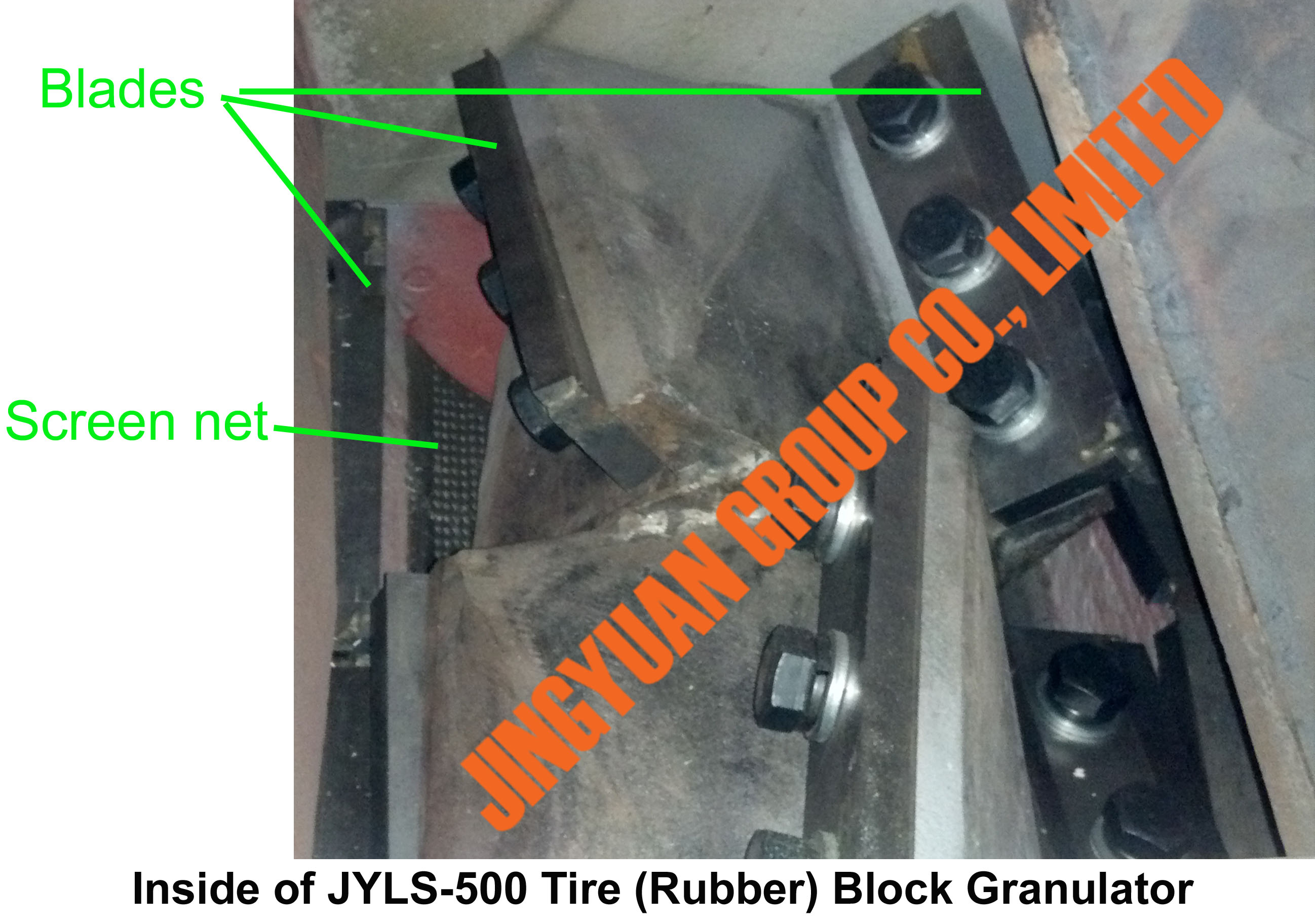

It is the machine to pulverize tire blocks or other rubber blocks into granules, the output size is controlled by screen nets, you can install different size of screen net to get different size of rubber granules, and it use YG10 Tungsten steel (high quality hard alloy) as its blades.

Structure

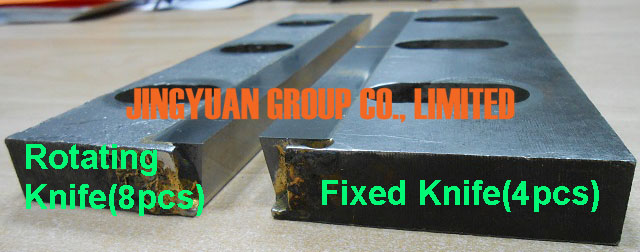

It mainly consists of frame, motor, main shaft, pulverizing mechanism, feed hopper, pulverizing chamber, 8 rotating knives, 4 fixed blades, screen net, etc.

Principle

Feed material via the feeding hopper, the motor drive the main shaft and rotation knives rotate, to make relative motion with fixed blades, so that to shear the tire (rubber) blocks into granules till the granule come out through the screen net holes and be collected by the outlet hopper.

Specification and Prices

| Model | JYLS-500 |

| Power: | 22kw |

| Dimension: | 1.2×1.2×1.5m |

| Weight: | 1300kg |

| Shaft Rotation Speed: | 600rpm |

| Input: | ≤5cm Tire blocks or other rubber blocks |

| Output: | ≤6mm Rubber granules mixed with steel wire or fly fiber. |

| Capacity: | 200-300kgs/hour |

| Knife Quantity: | 12pcs(8 rotation knives and 4 fixed knives) |

| Blade Material: | YG10 Tungsten Steel |

| Knife Hardness: | 92HRA |

| Delivery Lead Time: | 10days(Exclude Legal Holiday). |

| Price: | Please Contact us to inquire |

Function Sketch and Main Part

Function Sketch of JYLS-500 Rubber Granulator

Knives and Screen Net Location in JYLS-500 Rubber Granulator

Rotation Knife and Fixed Knife of JYLS-500 Rubber Granulator

Output Photo

Due to Steel Radial Tire only contain rubber and steel wire, almost no fiber inside, so that Steel Radial Tire Blocks from JYQK-45 Tire Block Cutter or from Tire Shredder Machines can be crushed by this machine to rubber granule directly as below photo showing.

Steel Radial Tire Granules from JYLS-500 Rubber Granulator, you can use JYCX-200 Magnetic Conveyor to separate out the steel wire.

Due to Fiber Bias Tire and car tire sidewalls only contain rubber and fiber, almost no steel inside, Fiber Bias Tire Blocks from JYQK-45 Tire Block Cutter or from Tire Shredder Machines also can be crushed by this machine to rubber granule directly as below photo showing.

Fiber Bias Tire Granules from JYLS-500 Rubber Granulator,need to pass JYXF-500 Fiber Separator to Remove Fly Fiber, for ensuring no fiber fly in crushing process, need to use JYC-100 whirlwind collecting machine to collect the fly fiber which fly out from the machine in crushing process.

Due to car tires treads contain both Steel and Fiber, if crushed by this machine directly, it will cause the steel wire and fiber hook each, so that can not separate them completely, need to use JYQQ-750 Car Tire Sidewall Cutter to remove two sidewalls and JYCD-250 Car Tire Tread Amputator to Cut Tire Tread Ring into Tire Tread Belt, then use JYTGF-300 Car Tire Tread Belt Pulverizing line to Crush and Separate Steel Ply Rubber Granule and Fiber Ply Rubber Granule, then crush Steel Ply Rubber Granule and Fiber Ply Rubber Granule separately, or crush Steel Ply Rubber Granule with Steel Radial Tire Blocks and crush Fiber Ply Rubber Granule with Fiber Bias Tire Blocks,etc.

After removing the steel wire and fiber, you can use JYYZS-800 Circular Vibration Screen to Separate different size of rubber granule as below photo.

4-5mm Rubber Granule from JYLS-500 Rubber Granulator and Screen out by JYYZS-800 Circular Vibration Screen

3-4mm Rubber Granule from JYLS-500 Rubber Granulator and Screen out by JYYZS-800 Circular Vibration Screen

2-3mm Rubber Granule from JYLS-500 Rubber Granulator and Screen out by JYYZS-800 Circular Vibration Screen

If you use it to cut other rubber into granules, such as tire flaps, cable skin, shoe base, etc, due to various rubber has different colors, you will get different color rubber granules as below:

5-6mm Color Rubber Granule from JYLS-500 Rubber Granulator

Connection with other machines

JYLS-500 Rubber Granulator Connect a JYC-100 Collecting Machine

JYLS-500 Rubber Granulator Connect a JYXF-150 Fiber Separator

JYLS-500 Rubber Granulator Connect a JYXF-200 Fiber Separator

Two JYLS-500 Rubber Granulators Connect to Same JYXF-200 Fiber Separator and one Granulator Be Fed from Top

Two JYLS-500 Rubber Granulators Share Same JYC-100 Collecting Machine and Connected by JYCX-200 Magnetic Conveyor and Belt Conveyor

Two JYLS-500 Rubber Granulators Be Fed from Top and Connected to Same JYC-100 Collecting Machine

Photo of shipment

Two JYLS-500 Rubber Granulators In Container Ready For Shipment

JYLS-500 Rubber Granulators With Straight Connector on Top According to Buyer’s Requirement

JYLS-500 Rubber Granulators With Elbow Connector on Top According to Buyer’s Requirement

Video

![]() Attention Please: When making this video,

Attention Please: When making this video,  works well in China, but now it does not work in China, so that you can not contact us by

works well in China, but now it does not work in China, so that you can not contact us by  , if you want co contact us, please click here to contact us by other ways.

, if you want co contact us, please click here to contact us by other ways.

Ismail Sellem

looks very nice rubber granulator machine, can I use it to crush cable rubber skin into rubber granules which can be used to make rubber granules?

admin

Yes, Ismail Sellem, from this post, you can see a photo of color rubber granules, that is the granules made by this machine from different color of rubber cable skin.

Taha

Dears.

I want small rubber grinder as follow:

input: 20 mm tire chips free of steel and fiber

output: 3 mm rubber granules

capacity: 250 kg/hr of required size

I want main grinder only without feeding or discharge belts.

waiting your reply soon

best regards

Taha Fathy

admin

Hello,Taha, this JYLS-500 Rubber Granulator can satisfy your requirement exactly.

We just sent you an Email, please find our Email in your Email inbox or spam box, if you have more question, please replying our Email directly instead of comment here, Ok? If you did not receive the email, you can comment below to let us know, so that we can resend the Email.

Best regards,

Admin

Ashley Johnson

I lied that you said that having the proper granulator equipment is crucial to making certain that rubber and steel wire and fiber is separated. I would imagine that this would allow you to reuse and recycle rubber granules. I would be sure to purchase quality industrial equipment in order to provide quality work to my customers.

admin

Hello, Ashley, thank you for inquiry. Our sales tried to send the plant details to your Email, but all emails returned to us and with the notes as below:

The mail system

johsonley3@gmail.com host gmail-smtp-in.l.google.com[74.125.135.27] said:

550-5.1.1 The email account that you tried to reach does not exist. Please

try 550-5.1.1 double-checking the recipient’s email address for typos or

550-5.1.1 unnecessary spaces. Learn more at 550 5.1.1

could you please double check your Email spelling is correct or not?

Best regards,

Admin

Ron Booker

I appreciate that you explain to us what a cable granulator is made for. Personally, I wasn’t aware that cable granulators were made to pulverize tire blocks. You did a great job of explaining the functions of cable granulators.

admin

Hello, Ron Booker, the granulator can crush both tire blocks and cable skin into granules, but also can crush other various rubber products into granules, such as rubber sole(shoe base), rubber mat, rubber belt, rubber flap, etc.

Angel

Buenas Tardes

Estoy cotizando Granuladoras de caucho que pueda cubrir mis necesidades.

Producción: 300 – 500 Kg/Hr

Me gustaría tener información más detallada del producto.

Necesito saber: ¿Cuál es la relación de transmisión de las poleas con correas?

What is the transmission ratio of pulleys with belts?

Espero su respuesta

Atte.

Angel B.

admin

Hello, Angel, Thank you for inquiry. sorry, we can not read Spanish, but we understand what did you mean Bing Translator. We have sent the plant details to your email, now you can find the files in the inbox or spam box of your Email. Best regards, Web Admin

Hola, Angel, gracias por preguntar.Lo siento, no entendemos castellano, pero entendemos lo que dice tiene que ser traducido.Hemos enviado los detalles de la fábrica a su correo electrónico, y ahora puede encontrar estos archivos en la Caja de correo electrónico o en la Caja de correo basura.Saludos, administrador de red

Shankar Narayan

Hi, I’m from India. We manufacture rubber rollers. We get rubber scrap in strip form of size 5-6 mm thick and 20-25mm width. We need to convert to <4mm granules. Kindly send your quote for the same.

admin

Hello,Mr.Shankar Narayan, our system showing that you sent us Email asked the machine to make granules and machine to make granule into rubber tiles, right? We have replied your Email and sent you the plant details to crush the waste rubber into granules and the plant details to make the recycled rubber granules to rubber floor tiles. You can find the files in the inbox or spam box? Best regards, Web Admin

Angel

A query. Could you give me information about the electric motor? (Hz – Rev / min) in advance thanks.

admin

Hello, Angel, thank you for inquiry, we can customize the motor data according to your electricity supply system. Best regards, Web Master

Muralidharan

hi

requirement given below

input: 1-2 inch rubber

output: 3 mm rubber

capacity: 250 kg/hr

waiting your reply soon

best regards

Murali

admin

Hello,Muralidharan, thank you for inquiry, we already sent the plant which can satisfy your requirement to your Email, now you can find the file in the inbox or spam box of your Email, please. Best regards, Web Admin

D.N.SINGH

We have shredded 5cm x5cm pieces of Truck radial tire chips with wire and some fabric also. want to make 80 mesh crumb powder. capacity 1500-2000 kg per 8 hrs. Please suggest and offer best and minimum equipment to do this on FOB basis . Please note we are leading dealers in Rubber Processing machinery in India since last 50 years. Therefore give best price for best quality. Regards D.N.SINGH

Bruno Barros

Bom dia.

Preciso de uma linha para 1000kg hora de pneu.

Para granulado de 00-3mm.

O que vocês me sugerem?

Preços?

admin

Hello,Bruno Barros, thank you for leaving your comment here, we just sent the plant details of recycling 1000kgs/hour used tires to your Email, now you can find the file in the inbox or spam box of your Email, please. Best regards, Web Admin